In part 1 I talked about the mechanical and wiring portions of the conversion. In part 2 I will discuss software settings and usage along with operation. Now that the laser is mounted and wired it's time to burn some wood!

The LaserGrbl software lets you change some of the Grbl firmware settings on the controller board. I left everything as is except $3 which I had to invert so that the X and Y movements on the mill matched the output from the software.

I started out powering the laser using an old 1 amp variable voltage power supply I built many years ago. I figured 12 volts, 5.5 W, that's less then 1/2 an amp right? Wrong. My initial try with the included griffin example file (

look for the sample SVG - G Code folder) went well but after that the laser output started becoming erratic and would trail off after a few seconds. A quick test with a multimeter showed the power supply voltage was dropping to just 3 or 4 volts!

A week or so later when I got a fixed 12V 5A power supply I was able to start experimenting again. LaserGRBL lets you make custom buttons. Right click and choose Add Custom Button in the button bar at the bottom. This one turns the laser on at low power (25/255).

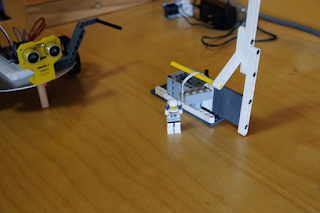

I do not have limit switches so Grbl uses the XY position at power on as home. I make sure the laser is positioned on the lower left area of the workspace when I power up and then use this low power laser on/off button to give me a low power dot to position the work piece. Getting the laser focused was tough because even at the low power setting the wood begins to burn after a few seconds. Focusing took some patience as I had to keep moving a scrap piece while turning the focusing ring and looking for the smallest dot. It paid off because now it draws very sharp lines. I am using scrap pieces of 1/8" mahogany construction grade plywood.

After experimenting with laser power settings and feed speeds I came up with a combination that gave good clean lines and corners. I drew the iceboat outline by tracing a photo using Aspire and then exporting it in svg format. LaserGrbl generated the CNC code from the .svg file. On import the software asks for the feed speed and laser power settings. The code did not complete the lines in a logical order, often wasting time jogging back and forth. I still need to investigate why this is happening.

Doing something with grey scale in it like a photo is the next challenge. Wood is either burned or not. LaserGrbl creates grey scale areas by using dots, the more space between the dots, the lighter the shade. The trick seems to be feeding LaserGrbl with a photo that is comprised of a narrow scale from light to medium grey.

I imported this grey scale file to try some test strips at different feeds and power settings.

Coming up I'll experiment with photos some more and then move on to cutting paper and wood.